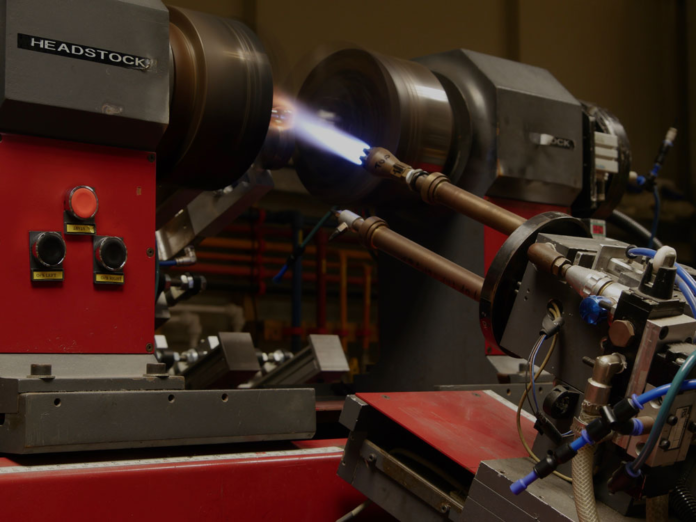

Automation in glass manufacturing has revolutionized the industry, bringing numerous advantages that have greatly improved productivity, efficiency, and product quality. With the use of advanced technologies and automated systems, glass manufacturers have been able to streamline their production processes, reduce labor costs, minimize errors, and achieve higher levels of precision in glass fabrication.

Increased Productivity:

Automation in glass manufacturing has significantly increased productivity by reducing production time and increasing output. Automated systems can handle repetitive tasks with high speed and precision, leading to faster production cycles and higher production volumes. Automated glass cutting, grinding, polishing, and drilling machines can process glass sheets with minimal human intervention, resulting in improved productivity levels compared to traditional manual methods. Moreover, automation enables glass manufacturers to operate their production lines round the clock, optimizing the utilization of resources and maximizing production capacity.

Improved Quality:

Automation has played a pivotal role in improving the quality of glass products. Automated systems are designed to perform tasks with high accuracy and repeatability, resulting in consistent product quality. In glass manufacturing, precision is crucial as even small variations in dimensions or surface finish can affect the final product’s performance and aesthetics. Automated glass fabrication processes ensure that each piece is cut, shaped, and polished to precise specifications, resulting in uniformity and consistency in the final product. Automation also reduces the likelihood of human errors, such as incorrect measurements or inconsistent processing, which can compromise product quality.

Enhanced Safety:

Glass manufacturing involves handling sharp, heavy, and fragile materials, which can pose safety risks to workers. Automation in glass manufacturing has significantly enhanced safety in the workplace by reducing the need for human intervention in hazardous tasks. Automated systems can perform tasks such as glass cutting, grinding, and handling heavy glass sheets, eliminating the risk of accidents and injuries associated with manual handling. Furthermore, automated systems are equipped with advanced safety features, such as sensors, guards, and emergency stop buttons, which ensure that the production process is carried out in a safe manner.

Cost Savings:

Automation in glass manufacturing has led to significant cost savings for glass manufacturers. Although the initial investment for setting up automated systems can be substantial, the long-term cost savings in labor, material, and operational expenses outweigh the initial costs. Automated systems can perform tasks with high speed and efficiency, reducing labor costs associated with repetitive and labor-intensive tasks. Automation also minimizes material wastage by optimizing the use of raw materials, as automated systems are designed to maximize yield and minimize scrap. Moreover, automation improves operational efficiency by reducing production downtime, minimizing errors, and optimizing production schedules, leading to cost savings and improved profitability.

Flexibility and Customization:

Automation in glass manufacturing has enabled glass manufacturers to achieve higher levels of flexibility and customization in their production processes. Automated systems can be programmed to handle different glass types, sizes, and shapes, allowing glass manufacturers to produce a wide range of glass products with ease. This flexibility allows glass manufacturers to quickly adapt to changing market demands and produce customized glass products to meet customer requirements. Automated systems also enable quick changeovers between different glass fabrication processes, allowing glass manufacturers to switch between different production runs efficiently and with minimal downtime.

Increased Innovation:

Automation in glass manufacturing has spurred innovation in the industry by enabling the development of new glass products and applications. Automated systems have expanded the possibilities of glass fabrication by allowing glass manufacturers to create complex and intricate glass designs that were impossible with traditional manual methods. Automated glass cutting and shaping machines can produce intricate patterns, curves, and bevels with high precision, opening up new design possibilities for architectural glass, automotive glass, and decorative glass applications. Automation has also facilitated the integration of smart technologies into glass products, such as smart windows and display glass, which have enhanced functionality and performance.

Consistency and Reproducibility:

Automation in glass manufacturing ensures consistent and reproducible results in glass fabrication processes. Automated systems are programmed to perform tasks with high accuracy and repeatability, ensuring that each glass product meets the same specifications and quality standards. This consistency in product quality is particularly important for glass manufacturers who need to meet strict industry standards, such as those for safety glass or optical glass. Automation eliminates the variations that can occur with manual processes, such as differences in operator skills, fatigue, or human errors, ensuring that the final glass products are consistent in terms of dimensions, surface finish, and other specifications.

Also Read: The Benefits of Automation in Manufacturing

Conclusion:

Automation in glass manufacturing has revolutionized the industry, bringing numerous advantages that have transformed the way glass products are fabricated. From increased productivity and improved quality to enhanced safety, cost savings, and innovation, automation has had a profound impact on the glass manufacturing processes. It has enabled glass manufacturers to optimize their production processes, reduce labor costs, minimize errors, and achieve higher levels of precision in glass fabrication.